Welcome to our complete guide to understanding Modbus, a widely used communication protocol in various industries. Modbus is a simple, yet powerful protocol that enables communication between devices and systems. Its popularity is due to its ease of implementation and ability to communicate with different types of devices, making it a versatile solution for various applications.

In this guide, we will provide a comprehensive overview of Modbus, including its protocol, implementation, and communication capabilities. Whether you’re new to Modbus or looking to deepen your understanding, this guide will equip you with the knowledge to utilize Modbus in your industry-specific scenarios.

Key Takeaways

- Modbus is a widely used communication protocol in various industries

- Modbus is a simple and powerful protocol that enables communication between devices and systems

- Modbus is easy to implement and can communicate with different types of devices

- This guide will provide a comprehensive overview of Modbus, including its protocol, implementation, and communication capabilities

- By understanding Modbus, you’ll be well-equipped to utilize it in your industry-specific scenarios

What is Modbus?

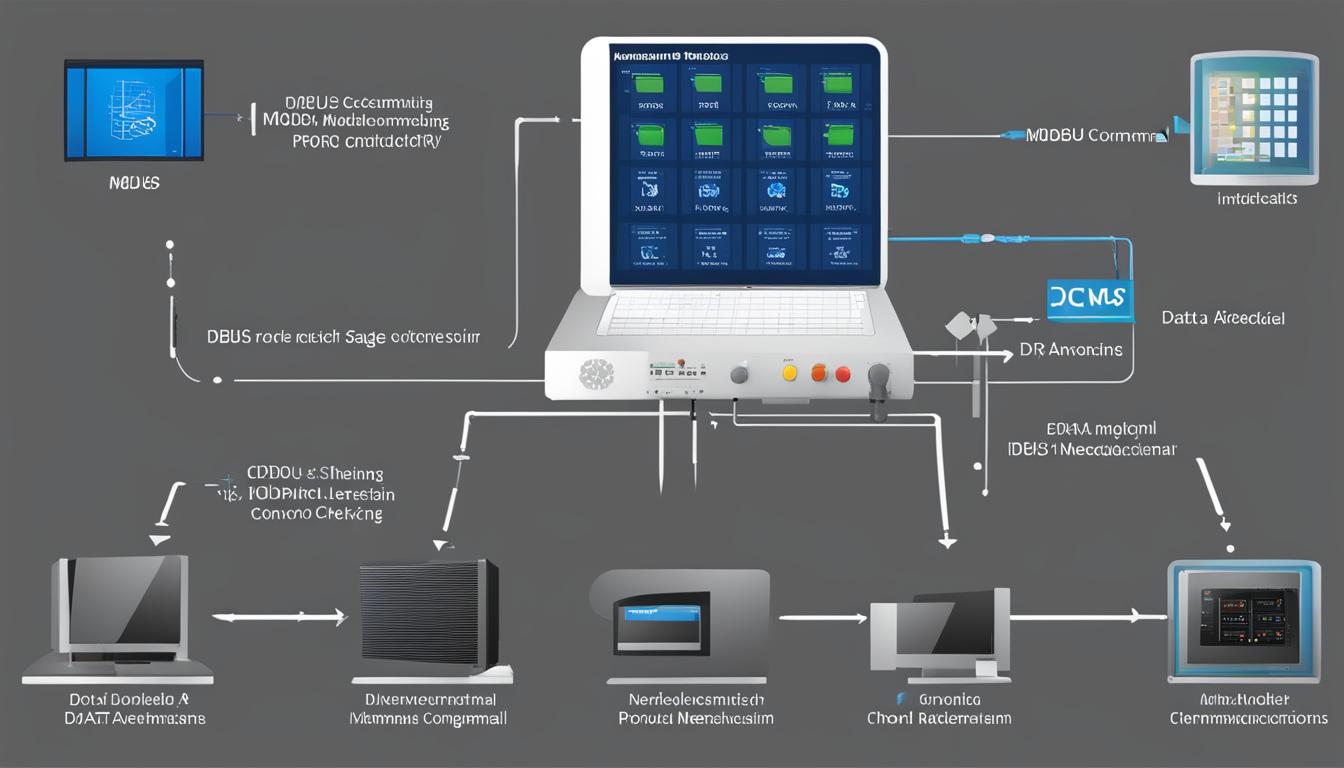

Modbus is a widely used communication protocol in various industries. It is a simple, yet robust protocol, designed for data transmission between devices in a network. At its core, Modbus is an application-layer protocol, meaning it operates independently of the physical layer, and is used primarily for device-level communications.

Modbus implementation involves two primary components: the Modbus master and the Modbus slave. The Modbus master device initiates communication and requests data from the slave device, which then responds with the requested information.

The protocol itself is relatively simple and straightforward, utilizing a request-response message structure. The Modbus protocol consists of a set of function codes, each with a specific purpose for data exchange between devices.

For example, function code 03 is used to read the holding registers of a Modbus slave device, while function code 06 is used to write to a single register. The Modbus protocol also supports error detection and correction, ensuring accurate data transmission between devices.

Modbus Communication Basics

In Modbus communication, data is transmitted between devices using a master/slave architecture. The master device initiates the communication and sends requests to the slave devices, which respond with the requested data.

The communication structure in Modbus is divided into frames or messages, which consist of five parts:

- Slave address: This identifies the slave device that will respond to the request.

- Function code: This indicates the type of action to be taken by the slave device, such as reading or writing data.

- Data: This contains the actual data being transmitted, such as sensor readings or control signals.

- Error check: This is a two-byte code that confirms the accuracy of the message.

- Timeout: This specifies the time limit for a response from the slave device. If this limit is exceeded, the master device will initiate a timeout error.

Modbus communication can use either a serial or Ethernet connection, with the latter being the more popular option due to its faster data transfer rates and larger network capacity. For serial communication, Modbus protocol can use two modes: Modbus RTU and Modbus ASCII. Modbus RTU is more widely used due to its simpler structure and higher efficiency.

In terms of data transmission, Modbus uses a variety of message types, including:

- Read Coils: This reads the status of digital output devices.

- Read Discrete Inputs: This reads the status of digital input devices.

- Read Holding Registers: This reads the values of analog output devices.

- Read Input Registers: This reads the values of analog input devices.

- Write Single Coil: This writes a new value to a digital output device.

- Write Single Register: This writes a new value to an analog output device.

- Write Multiple Coils: This writes multiple new values to digital output devices.

- Write Multiple Registers: This writes multiple new values to analog output devices.

Example Table of Modbus Message Types

| Message Type | Description |

|---|---|

| Read Coils | Reads the status of digital output devices. |

| Read Discrete Inputs | Reads the status of digital input devices. |

| Read Holding Registers | Reads the values of analog output devices. |

| Read Input Registers | Reads the values of analog input devices. |

| Write Single Coil | Writes a new value to a digital output device. |

| Write Single Register | Writes a new value to an analog output device. |

| Write Multiple Coils | Writes multiple new values to digital output devices. |

| Write Multiple Registers | Writes multiple new values to analog output devices. |

Understanding the basics of Modbus communication is crucial for its implementation, whether as a master or slave device. Armed with this knowledge, one can explore the various applications of Modbus in different devices and networks.

Modbus Variants: TCP/IP and RTU

Modbus has two primary variants: Modbus TCP/IP and Modbus RTU. These variants differ in their communication methods, making them suitable for different applications.

Modbus TCP/IP

Modbus TCP/IP is a variant of Modbus that uses TCP/IP to transmit data over Ethernet networks. It is a fast and reliable method of communication that allows for greater flexibility in network topology. Modbus TCP/IP is commonly used in industries such as oil and gas, energy management, and building automation.

A significant advantage of Modbus TCP/IP is its ability to support multiple connections simultaneously. This feature enables multiple master devices to communicate with a single or multiple slave devices, improving the efficiency of large-scale systems. Additionally, Modbus TCP/IP supports longer cable lengths and provides more extensive data transfer capabilities than Modbus RTU.

Modbus RTU

Modbus RTU is a variant of Modbus that uses serial communication to transmit data. It is widely used in industries such as manufacturing, oil and gas, and agriculture. Modbus RTU uses a master/slave architecture, where a single master device can communicate with multiple slave devices.

A significant advantage of Modbus RTU is its simplicity, making it an excellent option for applications with limited resources or slower network speeds. Additionally, Modbus RTU has a more extensive range of compatibility with different devices and is widely supported across various platforms.

| Modbus Variant | Communication Method | Applications |

|---|---|---|

| Modbus TCP/IP | TCP/IP over Ethernet | Oil and gas, energy management, building automation |

| Modbus RTU | Serial Communication | Manufacturing, oil and gas, agriculture |

In conclusion, Modbus TCP/IP and Modbus RTU are two primary variants of the Modbus protocol, each with its own communication method, advantages, and applications. Understanding the differences between these variants is crucial in choosing the appropriate one for your specific industry needs.

Modbus Master/Slave Architecture

In Modbus communication, there are two types of devices: master and slave. The master device initiates communication, while the slave device responds to the master’s requests.

Let’s take a closer look at the roles and responsibilities of the master and slave devices in Modbus architecture:

Master Device

The Modbus master device controls the communication with the slave devices. It initiates requests to read or write data to the slaves and receives responses to those requests. The master device is responsible for setting the communication parameters, such as the baud rate, parity, and stop bits. It can also configure the slave devices and monitor their status.

Slave Device

The Modbus slave device responds to the master’s requests for data exchange. It receives requests from the master device and sends back responses with the requested data. The slave device does not initiate any communication on its own. Instead, it waits for the master’s requests and follows the commands received from the master device.

The Modbus master/slave architecture offers several benefits, such as flexibility, reliability, and scalability. It allows the integration of multiple devices in a network and enables secure data exchange between them.

Now that we understand the Modbus master/slave architecture, let’s explore the different applications of Modbus in various industries in the next section.

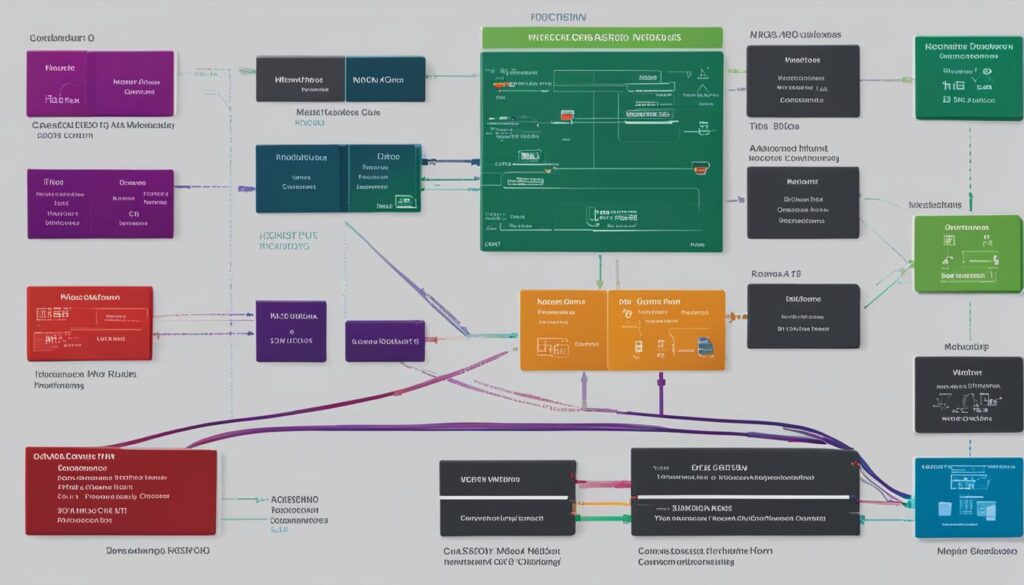

Applications of Modbus

Modbus is a versatile communication protocol that finds widespread use in various industries where devices need to interact and communicate with each other. Let’s take a closer look at some of the popular applications of Modbus:

Industrial Automation

Modbus is extensively used in industrial automation systems to exchange data between devices, including programmable logic controllers (PLCs), human-machine interfaces (HMIs), sensors, and other industrial devices. Modbus allows these devices to communicate with each other, enabling efficient and seamless automation processes.

Energy Management Systems

Modbus is also utilized in energy management systems to monitor and control building automation systems, such as heating, ventilation, and air conditioning (HVAC) systems, lighting controls, and power management systems. Modbus communication allows energy managers to optimize energy efficiency, reduce energy consumption, and lower energy costs.

Water and Wastewater Management

Modbus is used in water and wastewater management systems to monitor and control water treatment processes, ensuring efficient and effective operation of treatment plants. Modbus communication allows for remote monitoring and control of various devices, including flow meters, level sensors, and pumps.

Medical Devices

Modbus is also utilized in medical devices to exchange data between different devices, including patient monitors, infusion pumps, and ventilators. The use of Modbus communication in medical devices allows for improved patient safety, more efficient data retrieval, and seamless integration with electronic health records (EHR) systems.

Transportation Systems

Modbus is also used in transportation systems to exchange data between various devices, including traffic signal control systems, railway control systems, and airport baggage handling systems. Modbus communication allows for the efficient and effective management of transportation systems, enhancing safety, reducing congestion, and improving traffic flow.

The versatility and flexibility of Modbus make it suitable for a wide range of applications across different industries. From industrial automation to medical devices, Modbus continues to play a vital role in enabling seamless and efficient communication between devices.

Implementing Modbus Master

Implementing Modbus as a master device can be a complex process, but we are here to guide you through it step-by-step.

The first step is to ensure that you have a Modbus master device available that is compatible with your network. Once you have your device, you will need to configure the settings to match your network requirements. Common settings that must be configured include the Modbus slave devices’ addresses and communication parameters such as baud rate.

After configuring the settings, you will need to establish the connection between the Modbus master device and the slave devices on the network. This can be done using Ethernet or serial communication protocols, including Modbus RTU, Modbus TCP/IP, and others. It is recommended to use Modbus TCP/IP for Ethernet communication and Modbus RTU for serial communication.

To communicate with the slave devices, the Modbus master device sends requests to read or write the data stored in the slave devices’ registers. The master device must use the correct function codes for the type of request, and the register addresses and the data format must also be configured accurately.

It’s worth noting that the Modbus master device can send requests to multiple slave devices simultaneously, making it an ideal solution for multi-device control applications.

| Modbus Master Configuration | Description |

|---|---|

| Device Address | The unique address assigned to the Modbus master device in the network. |

| Baud Rate | The rate at which data is transmitted over the communication channel. Must match the baud rate of the Modbus slave devices on the network. |

| Function Codes | The codes that indicate the type of request being sent to the slave device. Common function codes include read coils, read inputs, write single coil, write multiple coils, read holding registers, and write holding registers. |

| Data Format | The format in which data is transmitted over the communication channel. Common data formats include binary, integer, float, and ASCII. |

As you can see from the Modbus Master Configuration table, there are various settings to consider when configuring a Modbus master device. These settings must be accurate for the Modbus master device to communicate effectively with the Modbus slave devices on the network.

Conclusion

Implementing Modbus as a master device requires meticulous settings configuration, establishment of proper connections, and accurate use of function codes and registers. However, once properly implemented, it provides unparalleled control over multiple slave devices on a network, making it an ideal solution for many industrial applications.

Implementing Modbus Slave

Implementing Modbus as a slave device requires a different set of steps and considerations than implementing it as a master device. In this section, we’ll guide you through the process of configuring and integrating Modbus slave devices into a network.

The first step in implementing Modbus as a slave is to ensure that the device is compatible with Modbus communication protocol. This can be done by checking the device’s specifications or consulting with the manufacturer. Once you’ve confirmed compatibility, you can proceed with the following steps:

- Configure the device’s Modbus address – each Modbus slave device on a network must have a unique address to allow the master device to communicate with it. The address is typically set using DIP switches on the device or through software configuration.

- Determine the Modbus register types and addresses – Modbus slave devices use registers to store and exchange data with the master device. Each register has a unique address that must be specified in the device’s configuration. The types of Modbus registers supported by the device will depend on its specifications.

- Set the device’s communication parameters – Modbus slaves must be configured with the same communication parameters as the master device, including baud rate, parity, data bits, and stop bits.

- Test the device’s communication – once the Modbus slave device is configured, it should be tested for proper communication with the master device. This can be done using Modbus diagnostic or monitoring software.

It’s important to note that the implementation process for Modbus slave devices can vary depending on the specific device and network configuration. We recommend consulting with the device manufacturer or a Modbus expert for more detailed guidance.

“Implementing Modbus as a slave device requires a different set of steps and considerations than implementing it as a master device.”

Modbus Registers: Understanding Data Exchange

Modbus communication relies on the exchange of data between devices, which is facilitated by Modbus registers. These registers are memory locations within Modbus devices that contain data values, and they play a crucial role in the effective functioning of Modbus communication.

There are four types of Modbus registers, each with a unique purpose and format:

| Register Type | Purpose | Format |

|---|---|---|

| Coils | Represents a single bit value for output devices | Boolean |

| Discrete Inputs | Represents a single bit value for input devices | Boolean |

| Holding Registers | Stores output data values for devices | Numeric (16-bit) |

| Input Registers | Stores input data values for devices | Numeric (16-bit) |

Note: The format for holding registers and input registers is 16-bit unsigned integer, which can store values from 0 to 65,535.

Modbus registers are referenced by their address, which is a unique identifier for each register within a Modbus device. When data is exchanged between Modbus devices, the address of the register being accessed is specified along with the quantity of data being transferred.

It’s important to note that Modbus registers have a limited quantity, which can vary depending on the device and implementation. Therefore, it’s crucial to manage and allocate these registers in a way that optimizes Modbus communication and avoids potential conflicts.

Understanding Modbus registers is essential for effectively implementing and utilizing Modbus communication in different devices and networks. By grasping the role and function of these registers, you can optimize the data exchange process and ensure efficient communication between Modbus devices.

Conclusion

We hope this guide has provided a comprehensive understanding of Modbus as a widely used communication protocol in various industries. By grasping the concepts covered in this guide, you’ll be well-equipped to utilize Modbus in your own industry-specific scenarios.

In this guide, we have explored the basics, variants, architecture, applications, and implementation of Modbus. We have discussed the purpose of Modbus as a communication protocol and how it’s implemented in different devices and networks. We have also highlighted the fundamental principles of Modbus communication, including its structure, message types, and data transmission.

Furthermore, we have examined the two primary variants of Modbus: Modbus TCP/IP and Modbus RTU, discussing their differences, advantages, and applications in different scenarios. We have also explored the master/slave architecture employed in Modbus communication, explaining the roles and responsibilities of the master and slave devices.

In addition, we have focused on the wide range of applications for Modbus in various industries, including how it’s used in different devices, networks, and industrial automation systems. We have also guided you through the process of implementing Modbus as a master or slave device, outlining the necessary steps and considerations.

Finally, we have discussed Modbus registers, which are essential for data exchange between devices. We have explained the different types of registers and their significance in Modbus communication.

Overall, we believe that Modbus communication protocol is an essential tool in the world of industrial automation and networking. It has the ability to establish communication between devices and systems that otherwise would not be able to communicate with each other. By understanding its basics, variants, implementation, and applications, you can unlock its full potential and achieve success in your industry-specific scenarios.

FAQ

What is Modbus?

Modbus is a widely used communication protocol in various industries. It is used for transmitting data between devices and systems, allowing them to communicate and exchange information.

How is Modbus implemented?

Modbus can be implemented in different devices and networks, such as programmable logic controllers (PLCs), remote terminal units (RTUs), and supervisory control and data acquisition (SCADA) systems. It uses a master/slave architecture, where the master device initiates the communication and the slave devices respond to requests.

What are the basics of Modbus communication?

Modbus communication follows a structured format, with messages consisting of function codes, data addresses, and data values. There are different message types, including read, write, and diagnostic messages. Data is transmitted using binary encoding and can be represented in different formats, such as 16-bit integers or floating-point numbers.

What are the different variants of Modbus?

The two primary variants of Modbus are Modbus TCP/IP and Modbus RTU. Modbus TCP/IP is used over Ethernet networks and utilizes the TCP/IP protocol, while Modbus RTU is a serial communication protocol used over RS-485 or RS-232 connections.

How does the Modbus master/slave architecture work?

In Modbus communication, the master device initiates the communication by sending requests to the slave devices. The slaves respond to these requests, providing the requested data or performing the requested operation. This architecture allows for efficient and organized communication between devices.

What are the applications of Modbus?

Modbus is widely used in various industries, including manufacturing, energy, and building automation. It is used to connect different devices and systems, allowing for seamless integration and data exchange. Modbus can be found in applications such as control systems, monitoring systems, and process automation.

How do I implement Modbus as a master device?

To implement Modbus as a master device, you need to configure the communication parameters, such as the baud rate and parity, on the master device. You also need to set up the slave devices and establish the communication channels. Once the setup is complete, the master device can send requests to the slave devices and receive the requested data.

How do I implement Modbus as a slave device?

Implementing Modbus as a slave device involves configuring the communication parameters, such as the address and data format, on the slave device. The slave device waits for requests from the master device and responds accordingly, providing the requested data or performing the requested operation.

What are Modbus registers?

Modbus registers are data storage areas used for data exchange between Modbus devices. There are different types of registers, such as input registers and holding registers. Input registers store data read from the slave devices, while holding registers store data that can be read from or written to by the master device.